Circular Economy

- Producing Fertilizers with Recycled Phosphate

- PolyStyrene Loop

- Promoting Circular Economy at ICL Rotem

In order to reach a low carbon footprint, resource efficient and competitive economy, there is a need to transition to a more circular economy. A system where the value of products, materials and resources is maintained in the economy for as long as possible. Simultaneously, this transition will reduce the generation of waste, save energy and reduce the rate of raw materials used. This change is part of the global efforts towards sustainable development.

In order to minimize its environmental impact at the end of a product’s life, ICL has embraced the ‘Integrated Industry’ approach. According to this approach, the industrial production process should shift from a linear process, in which resources and capital pass through the production chain and eventually become waste, to a circular process where waste can serve as input for other production processes.

As ICL develops more and more sustainable products from varied waste streams, there are also intense efforts to integrate its own products and byproducts into circular processes. ICL’s highly-integrated value chains use advanced processes which utilize by-products and waste products to enable the cost-efficient conversion of raw materials into higher value-added products. ICL is also developing a new hydro-process for precious metal recovery, designed for the recycling industry.

Joining the CR3 - Center for Resource Recovery and Recycling

As ICL expands its vision on the circular economy and resource, it is looking for relevant partnerships that can propel it forwards. Therefore ICL has joined the Center for Resource Recovery and Recycling, the CR3.

The CR3 The Center for Resource Recovery and Recycling (CR3) is committed to being a cooperative research center focused on sustainable stewardship of the earth’s resources. Its focus is on helping industry to create a sustainable future. The CR3 is helping to advance technologies that recover, recycle and reuse materials throughout the manufacturing process. This, creates opportunities to reduce energy costs and increase profitability, while protecting our natural resources.

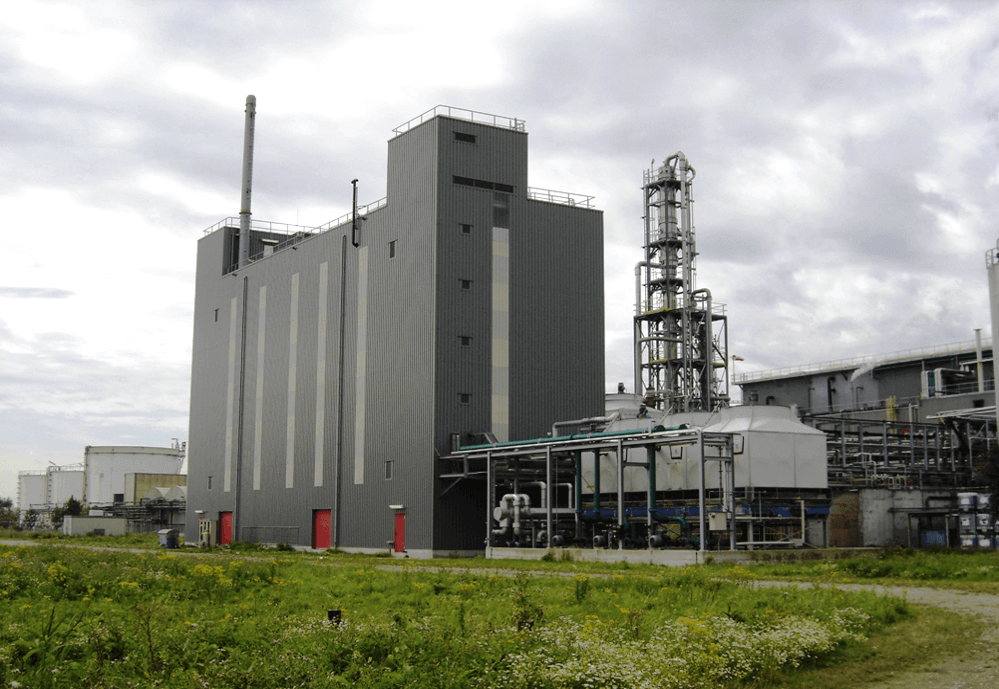

Energy in the Making - Using hydrogen by-product as fuel

In ICL’s Dead Sea site, the Bromine - Chlorine plant is producing Bromine and Chlorine for various industrial needs. During the chemical production, hydrogen is created. Until recently, the hydrogen, that was not used in the production process, or sold as compressed hydrogen, was released. In 2018, as part of an overall air emissions reduction initiative that required the incineration of certain gases, it was decided to use the hydrogen by-product as fuel (which has no emissions other than water vapor), instead of natural gas (a fossil fuel). Thereby, enabling the Bromine-Chlorine plant to reduce its air emissions without adding emissions that occur when burning fossil fuels.

In its Phosphate Solutions division, ICL is working on finding new sources of phosphorus, which is a necessary mineral for healthy plants, from sources other than phosphate rock, such as ash from sewage sludge, as well as, using by products from the production process as possible viable products. ICL is currently developing a new hydro-process for precious metals recovery, designed for the recycling industry. In the Industrial Products division, ICL is focused on retrieving bromine from various waste streams.

Closing The Loop - An EU Action Plan for the Circular Economy

The European Commission has adopted a new policy objective which aims to achieve a sustainable, low carbon, resource efficient and competitive economy. The Circular Economy Package includes a comprehensive commitment to eco-design, the development of strategic approaches for plastics and chemicals, a major initiative to fund innovative projects under the umbrella of the EU’s Horizon 2020 research program and targeted action in areas such as plastics, food waste, construction, critical raw materials, industrial and mining waste, consumption and public procurement.